Company

Metal casting since 1961 in Gorizia, Italy

By virtue of its wealth of experience, Roldo has taken on the role as contract supplier for various sector, ranging not only from shipbuilding to industrial, but also agricultural machinery and commissions.

Our history

The Roldo foundry started out as a family firm in 1961. This was during Italy’s economic boom when anyone with skill and ambition could set themselves up in business. Luigi Roldo, who at the time was working as a labourer in a long established foundry in Gorizia, did just this.

When the foundry where he worked decided to stop producing aluminium, Luigi and his brother-in-law Riccardo decided to go into it, and that’s how the business – which right up to the present day is run by the third generation of the Roldo family – began.

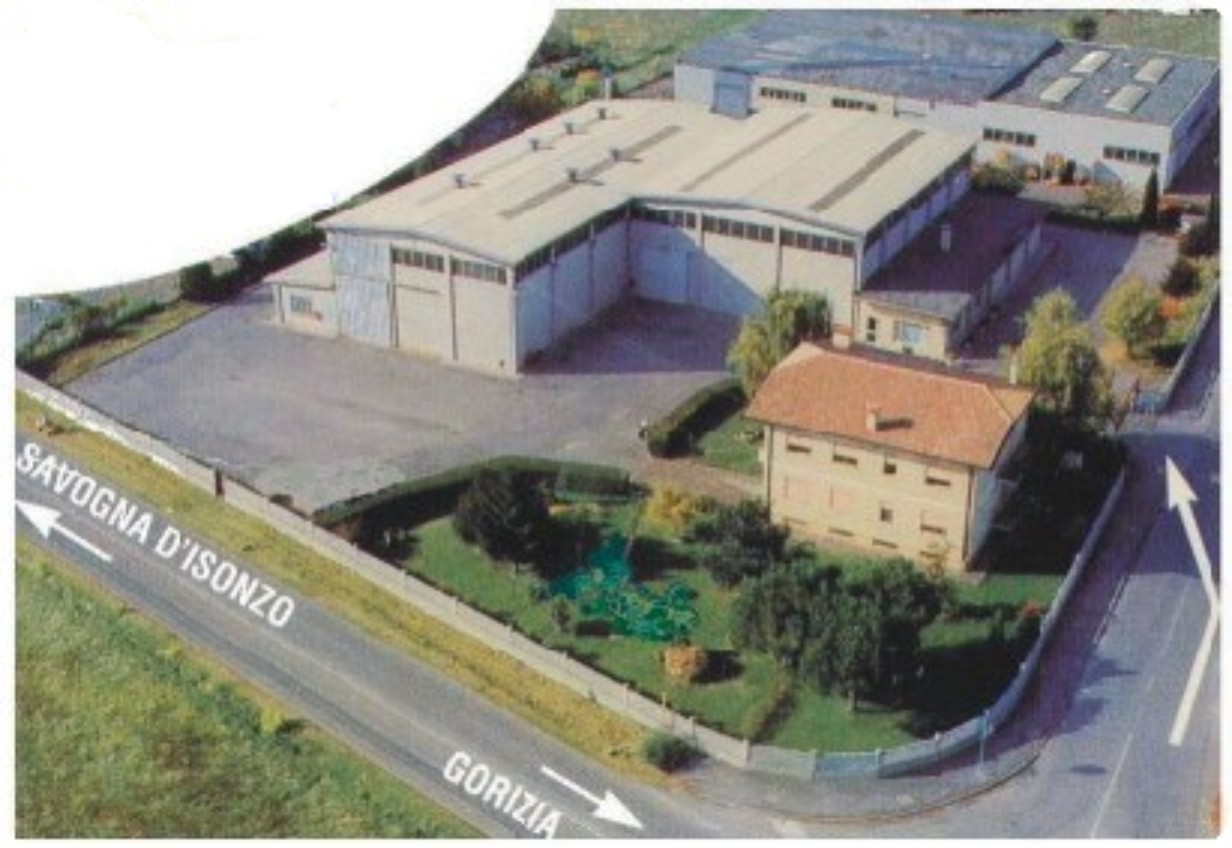

They started out in rented factory buildings, but as the foundry went from strength to strength, they decided to build their own production premises in 1976 which were further extended in 1985. Apart from the structural aspect, other changes took place within the company itself.

It went from being a small scale artisanal enterprise to a better equipped entity with more modern machinery able to cast aluminium, brass and cast iron.

As time passed the foundry added to sand casting also shell casting, a method which uses permanent moulds and which allows the production in series of larger numbers of castings with a more refined finish.

In addition to casting, the foundry began to carry out its own finishing work, where the rough castings are freed of excess metal (flashing, risers and runners) being subjected to sanding and, finally, also shotblasting.

If requested, the Roldo foundry can also contract out machining work to trusted partners for customers who required highly finished work.

By virtue of its wealth of experience, Roldo has taken on the role as contract supplier for various sectors, ranging not only from shipbuilding to industrial, but also agricultural machinery and artistic commissions.

Conscious of the constant innovation which is a characteristic of this sector, the foundry aims to conserve its current production methods while at the same time seeking further growth and modernization in order to take its own tradition forward intact into the future.

Readiness

We work closely alongside our customers from every aspect, but above all we do this in such a way their needs find a speedy and effective solution through us. We can carry out quick

Honesty

We believe that through our work it is more important to win a customer than win a sale, and therefore our philosophy is founded on the transparency with which we manage our contacts, on the fairness with which we calculate our quotation and on the quality of our product.

Flexibility

We can make adjustment on short notice, produce small batches, and work under tight deadlines.

Versatility

Throughout our history we have cast a range of metals: aluminium, bronze, cast iron, brass and lead. We have made the most bizarrely-shaped casting and have always attempted to find solutions wherever possible with the tools we have to hand.